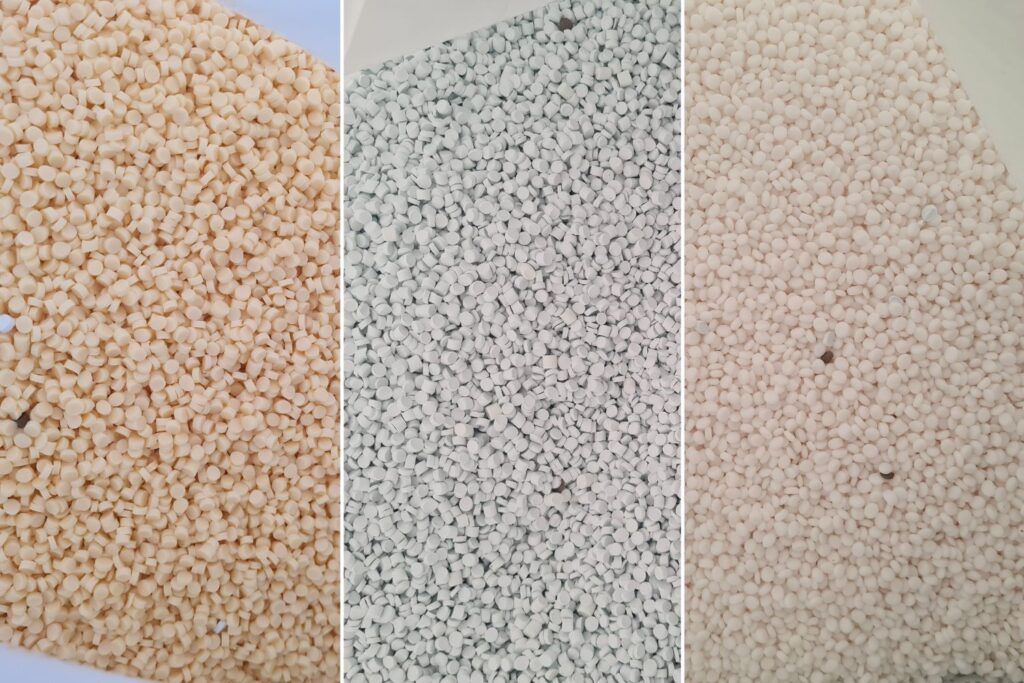

The production of moulded soles involves a variety of materials according to the requirements of comfort, strength, grip, and design. Although the first moulded soles were made of vulcanised natural rubber, today synthetic compounds are used, which can be composed of up to 15-20 different ingredients (e.g. sulphur, carbon, silicon) that profoundly influence the characteristics of the finished product.

Elastomeric material most used to produce soles. It is flexible, wear-resistant and offers good grip. Suitable for frequently used footwear and sneakers.

A lightweight, flexible material that offers good shock absorption without weighing down the shoe. It is often used for soles of sports shoes, running shoes and summer sandals.

Versatile material with properties of durability, flexibility, and wear resistance. It can be used in different densities to suit specific needs. It is ideal for everyday and work footwear. PU adapts to the foot, providing custom-made comfort.

Robust and wear-resistant material with high adhesion to the ground. Used for outdoor shoes such as hiking or trekking shoes and work footwear.

A lightweight, shock-absorbing material often used in the production of intermediate soles and for outer soles. It provides excellent cushioning by reducing impacts during walking. It is used in sports, running or training, and casual shoes.

Gel pads can be incorporated into the soles to provide additional cushioning and comfort. It provides better stability and comfort. It is incorporated into high-performance running shoes and specialised sports shoes, such as tennis or basketball shoes.

Lightweight, weatherproof, and abrasion-resistant material. Mainly used for work and casual shoes.

Material with high capacity to adapt to the shape of the foot. This viscoelastic material offers customised support, distributing weight evenly and reducing pressure on specific areas. Ideal for everyday footwear.

Durable textile materials, such as nylon or polyester, can be integrated into the sole to ensure lightness and breathability. They allow greater ventilation of the foot and are often coupled with antibacterial layers to maintain a healthy environment inside the shoe.

Materials such as carbon or fibreglass can be incorporated into soles for added durability, rigidity, and support. It is used in professional and competition running shoes.

Used to add flexibility and comfort to the sole. It is temperature-resistant and effectively absorbs shock. Perfect for walking, casual and orthopaedic shoes.

Flexible and durable material, often used to produce inserts in soles to improve cushioning. Used in multifunctional sports and hiking shoes.

The choice of sole materials depends on the type of footwear, the intended use, and the desired design. Moulded soles can be made from a combination of these materials to achieve the desired characteristics.

Learn more about the world of moulded soles.

VAT IT02377230970 | Cap.Soc. € 35.000 i.v. – REA PO 529606 – Pec: cbcsrlprato@pec.it | Cookie policy | Privacy policy | Credits

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

This website uses the following additional cookies:

(List the cookies that you are using on the website here.)

Please enable Strictly Necessary Cookies first so that we can save your preferences!