Discover more

Perseo system was born in 2013 out of an unfulfilled necessity: a soles manufacturer needed to store the heavy sole moulds inside an automatic warehouse to improve picking times and reduce the physical effort of the operator.

Since that day, we have developed Perseo Matrix single-tray automatic warehouses with small bays to manage one or few items. This way the operator can have the required articles available at once.

Each automatic warehouse is custom-made and suitable for various sectors: from leather to rubber, and even textile.

Our range of solutions extends to Perseo Handling logistics system to automatise the management of materials, as well as the preparation of the full package to send to clients. This system is also completely custom-made and adaptable to any type of enterprise.

Perseo automatic warehouse and logistics systems are both designed to:

Perseo products are divided into two categories:

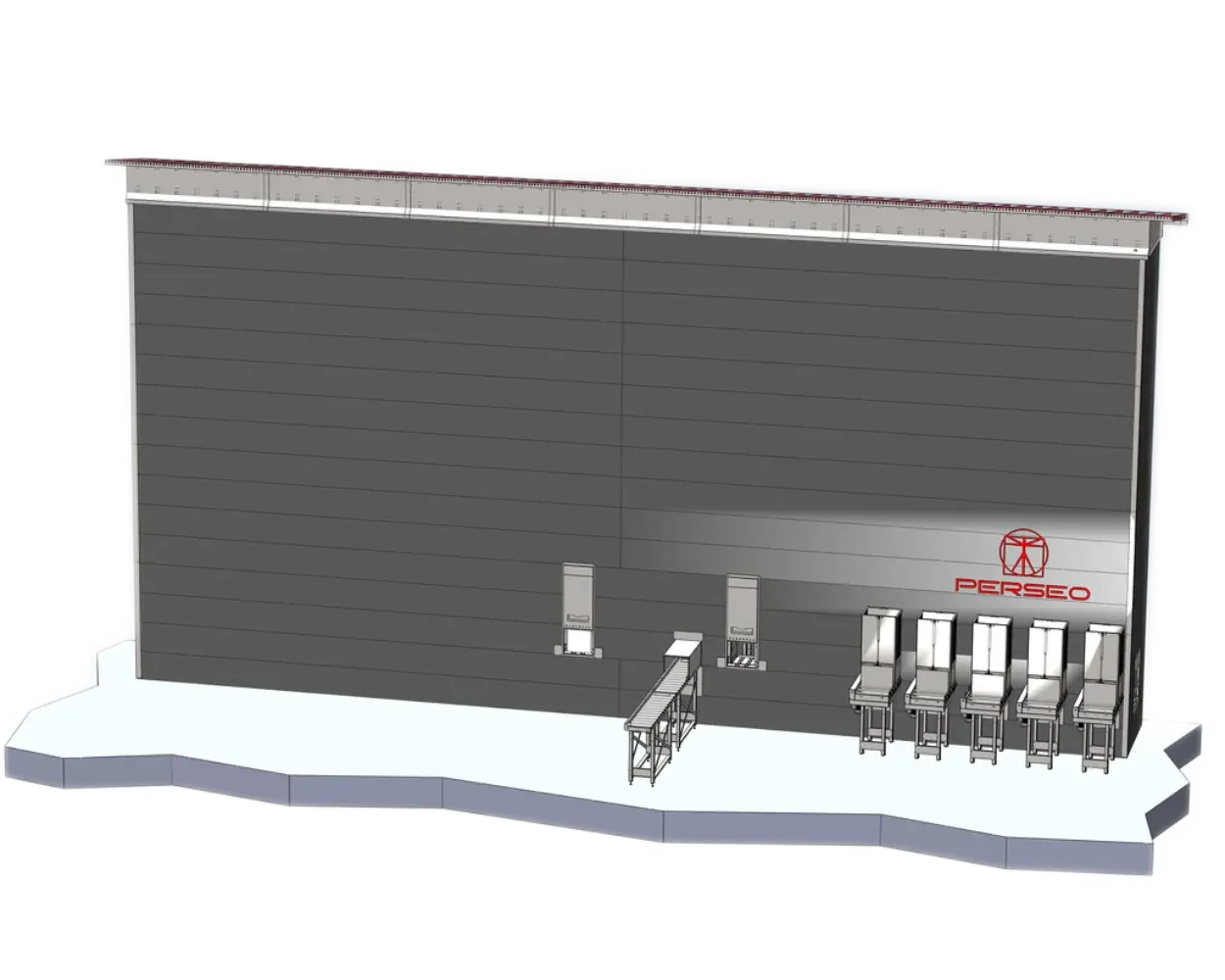

Perseo warehouses allow to manage a single or a few objects per tray, so that the operator can immediately find the articles necessary for the production. Its anti-seismic structure is covered with insulated panels. Each warehouse can be installed inside or outside of the factory.

Automatic warehouse designed for the sole factory to manage and handle sole moulds of all types and sizes. Small bays handle one mould at a time and are equipped with the easy extraction system to reduce the physical effort of the operator.

Automatic warehouse dedicated to the fashion industry such as leather goods or shoe manufacturers. Manage all the components used, of all sizes (dye bottles, thread spools or lasts), in small trays according to the bill of materials.

Perseo Handling logistics system permits to automatise entire production phases, saving operators from having to do repetitive tasks that may endanger their health.

Each system is custom-made to adapt to the specific necessities of every client, changing depending also on the daily workload.

Logistics system that manages whole or cropped fabric rolls. Thanks to the roller conveyor and shuttle, the structure automatically prepares the boxes that will be delivered to the customer, without effort and improving preparation times.

Automations can be integrated in the Perseo systems but can also be installed independently. The objective is to improve the management of items by handling the bill of materials (B.O.M.) and reducing picking and preparation times for the operators.

Discover all Perseo brand automations:

It recognises, registers and codes each mould, of any type and size, entered in the Perseo Matrix Moulds automatic warehouse. It keeps track of each article, and it is possible to consult the movement history.

Reduce machine time and automate the entire picking or deposit cycle. Install the loading and unloading roller conveyor in the Perseo Matrix Moulds automated warehouse. Compatible with any type of mould.

The automatic rolling machine with cutting machine is perfect for cutting and preparing sample rolls to send to customers. Improve production times and reduce physical effort for the operator, no need to search the fabrics in the storage department.

Perseo products optimise the speed of picking articles. There is no need to search for and collect items from the shelves. The system is completely automated and improves the company’s production process by assisting with order preparation.

Every Perseo automatic warehouse is equipped with a customised human-machine interface, tailored to the needs of the customer. The system is equipped with a simple and intuitive PC touch screen that shows the real-time content inside the plant.

Linking Perseo structures with the company’s ERP management represents an advantage for the Industry 4.0 and 5.0 incentives. It makes it possible to automatize and optimise the production process, preparing orders according to the bill of materials.

Perseo systems can be controlled remotely, keeping track in real time of the presence and position of each article. Everything inside the structure is automated and monitored. There is no risk of losing items or components placed on the shelves.

Eliminate physical effort and prevent occupational diseases among operators. Rather than having to pick up and place heavy items on the shelves from uncomfortable positions, all procedures will instead be automatically controlled and managed.

We specifically develop each Perseo system by listening the customer’s needs, in accordance with daily workload, types of articles to handle, available space in the department. Our customers’ necessities are at the centre of our work ethic.

VAT IT02377230970 | Cap.Soc. € 35.000 i.v. – REA PO 529606 – Pec: cbcsrlprato@pec.it | Privacy Policy | Cookie Policy