Perseo Matrix Fabrics is the automatic warehouse designed for semplifying the most repetitive and laborious phases in the textile sector.

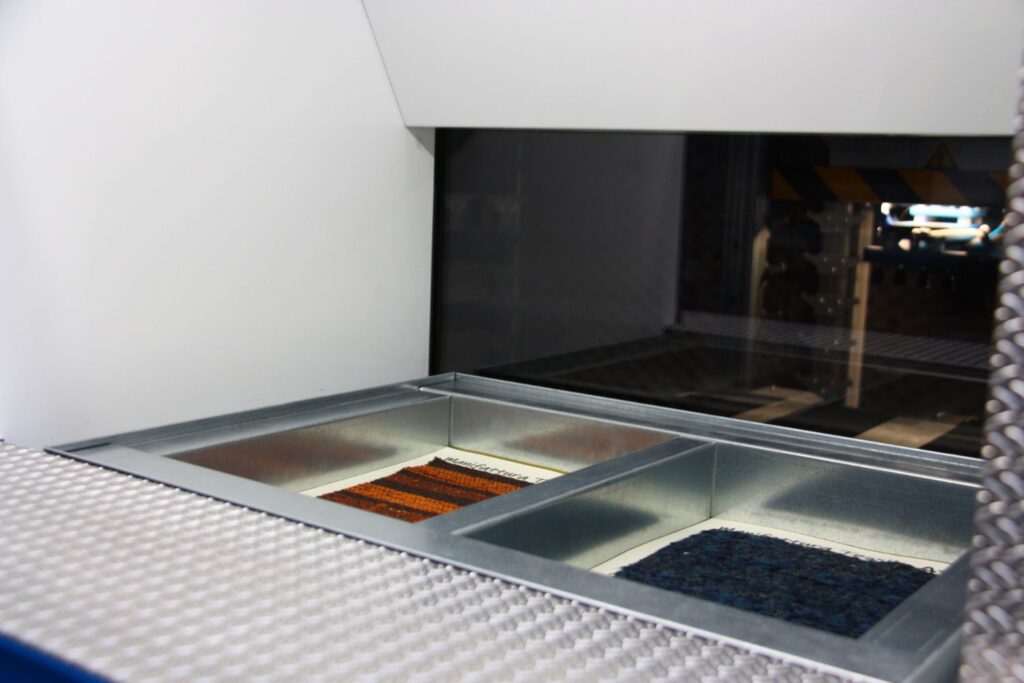

Perseo does not have one single drawer moving a high number of articles, rather a set of trays for handling each single item such as fabric rolls and selections (swatch and colour cards).

Each article is handled as needed, according to the bill of materials.

While the operator carries out a task, the system prepares another article in masked time, reducing machine run times. This way the worker does not waste time looking for items on the shelves and will find them already on the bay.

Perseo Matrix Fabrics automatic warehouse is ideal for companies working in the textile sector that rely heavily on the sample department, with many sample cuts and colour cards. These companies are looking for a modern automated management with a “goods-to-person” system that might prevent the operator from having to move continuously while searching and preparing samples.

Everything is custom made, based on the space available in the production plant and the workload established by the bill of materials. Perseo can be personalised with its dedicated automations such as the pneumatic manipulator and the automatic rolling machine with cutting machine.

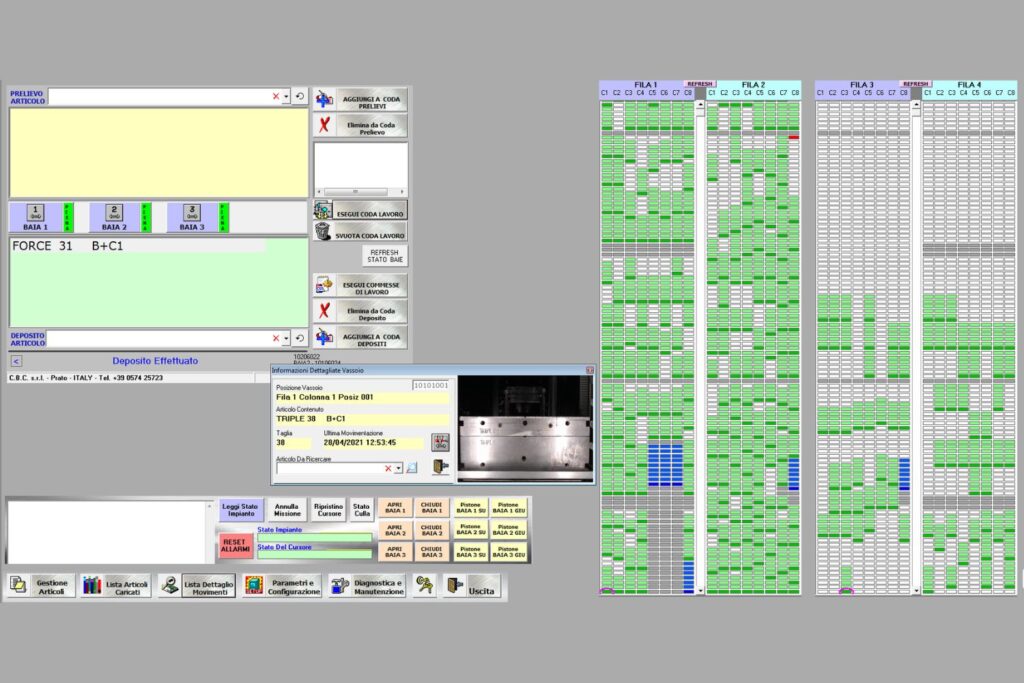

Each automatic warehouse for the textile sector is equipped with a computer with touch screen, in which the simple and intuitive software showing the internal synoptic of the warehouse.

The PC screen shows all the positions in the warehouse, immediately identifying those that are occupied and those that are vacant.

The warehouse software can be connected to the Enterprise Resource Planning (ERP) and directly prepare the trays included in the bill of materials.

In the case of emergencies or last-minute work, the operator can pick articles by clicking on the warehouse screen, manually and no longer automatically.

Only the trays containing the items to be prepared and shipped to the customer will be handled, resulting in significant energy savings, and reducing picking times.

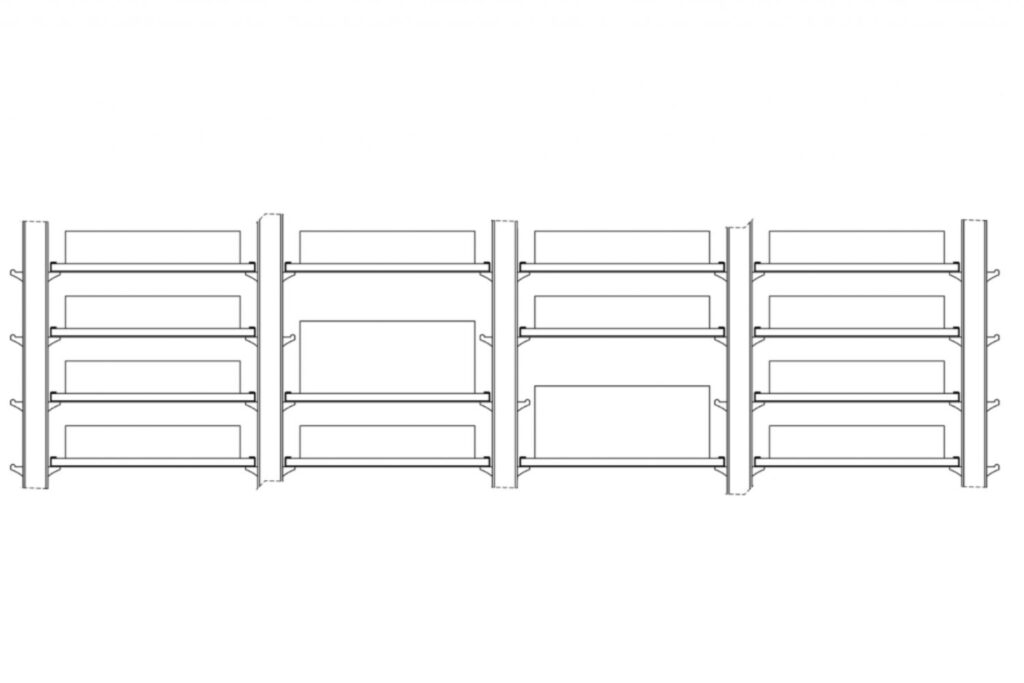

The key strength of the automatic warehouse for the textile industry Perseo Matrix is the Matrix System, which can manage articles at different heights, optimising space without losing volume.

Pieces with different diameters and many swatch colour cards can thus be managed, allowing a significant economy of space.

Once the items are placed in the tray, the system detects their height and places them in the warehouse, using only the space required.

The advantages of the matrix system are:

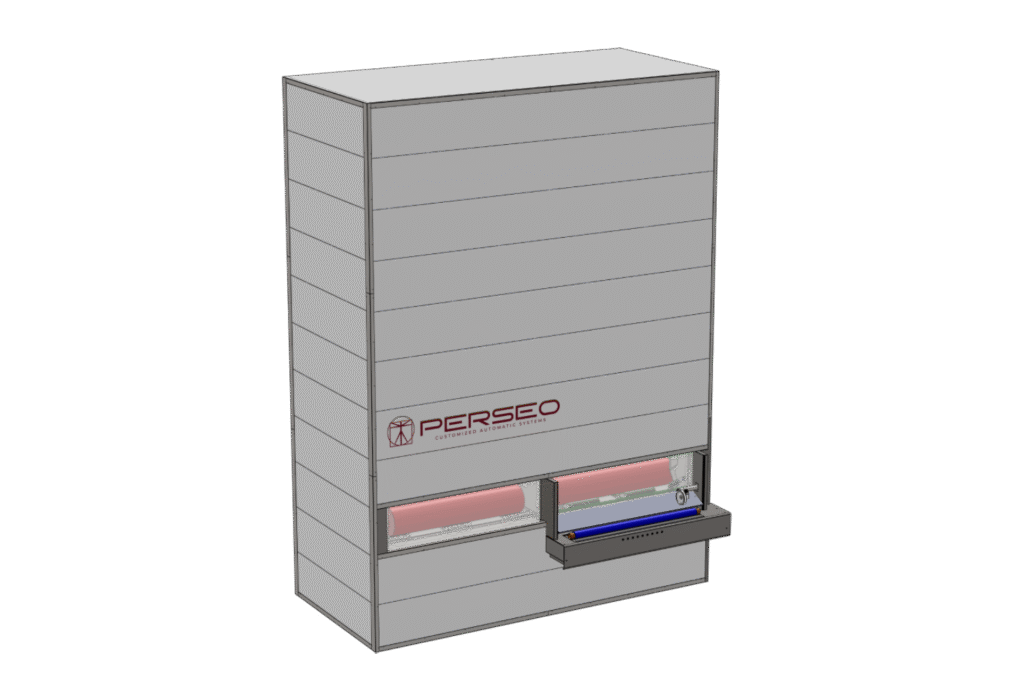

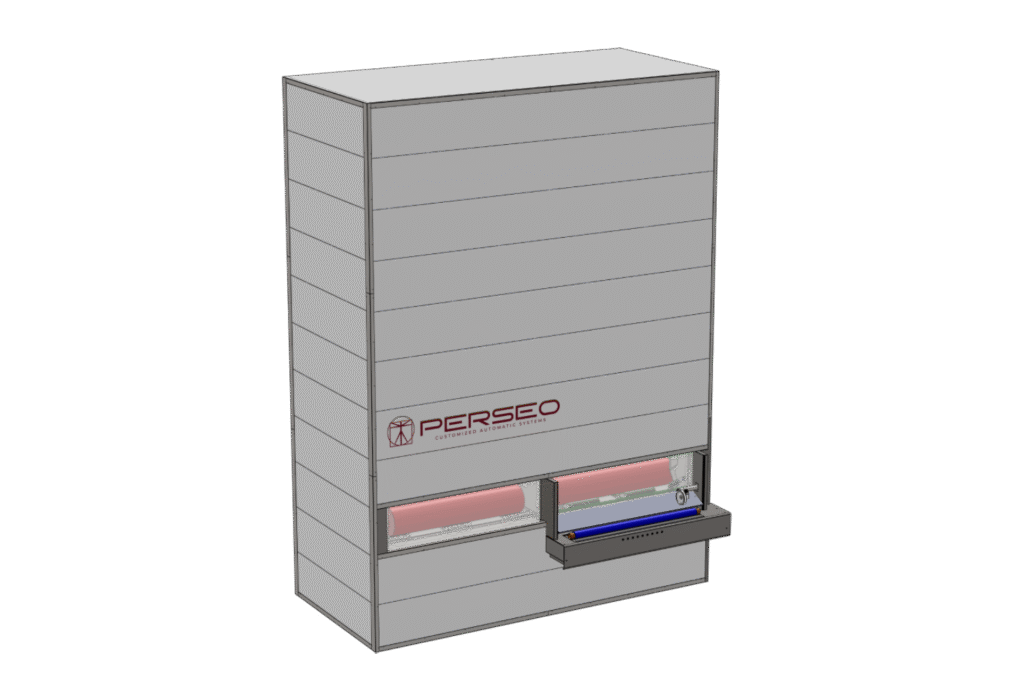

The automatic warehouses for the textile sector Perseo Matrix are not pre-packaged but are custom-built according to the specific requirements of each customer.

The structure consists of several elements: the main body formed by one or more access bays, the computer, and the electrical panel. Additional elements can be added both vertically or horizontally, personalising each plant.

Given the type of stored items, we recommend installing Perseo Matrix Fabrics inside the production plant, however on request it can also be installed outside with an adequate air conditioning system.

The Perseo automatic warehouses already built are 10 metre high and 16 metre long.

The Perseo automatic warehouses already made are up to 10 metres high and up to 16 metres wide.

On request, some automations can be added to complete the automatic warehouse:

Automatic rolling machine with cutting machine

Pneumatic manipulator

On request, Perseo automatic warehouse can be equipped with a rolling machine with cutting machine, eliminating time spent searching for fabric rolls and physical effort from having to move them manually.

Our philosophy for the vertical automatic warehouse is not limited to the storage of fabric pieces but extends to an automation that fulfils all the tasks necessary to the preparation of sample cuts.

The warehouse stores the fabric rolls inside and, depending on the bill of materials, carries them to the bay or directly to the rolling machine with cutting machine.

Advantages:

For a textile company, the manual selection of colour cards is a long and repetitive task.

With Perseo automatic warehouse this process is completely automated and active 24 hours a day, keeping selections always ready for shipping.

Upon request it is possible to install the manipulator which autonomously selects the cards present in the bill of materials and readies them for delivery to the customer, with no need of human intervention.

Advantages:

Pieces searches and shade card preparation are nil for the operator. The vertical development of the warehouse Perseo Matrix Fabrics frees up valuable space in the sample department.

Each machine is equipped with a tailor-made human-machine interface that enables understock management. The system warns what is available and what is about to run out to replenish the stock.

The system can be managed remotely so that selections can be ordered everywhere. The warehouse is active H24 and can always prepare the selections to be sent to the customer.

Perseo can be connected directly to the enterprise resource planning, automatizing tasks according to the bill of materials. An advantage the 4.0 and 5.0 Industry incentives.

All Perseo warehouses are earthquake-proof and comply with work safety ruler. The structure is independent and separate from the warehouse whether it is installed indoors or outdoors.

In the Perseo automatic warehouse, all picking, and storage operations are performed with a minimum power consumption of less than 1.5 kWh. Can be connected to a 380 V socket.

VAT IT02377230970 | Cap.Soc. € 35.000 i.v. – REA PO 529606 – Pec: cbcsrlprato@pec.it | Privacy Policy | Cookie Policy