What are the advantages of the automatic warehouse Perseo Matrix Moulds with Preheating Ovens?

Sole Factory - 21 June 2024

The automatic warehouse Perseo Matrix Mould with Preheating Ovens optimises the entire production process. The installation of this solution brings many advantages. Thanks also to the interconnection, there are energy savings, reduced operator fatigue, no downtime and space recovery. In detail: 1. Interconnectivity The installation...

Discover more

Discover more

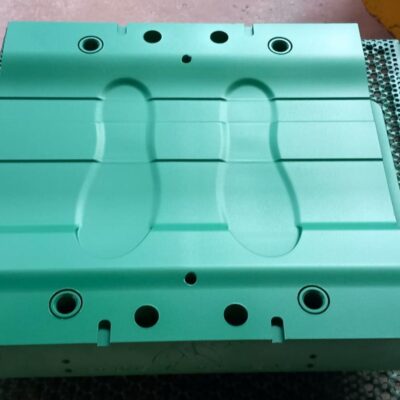

Some surface treatments are made to improve the extraction of the sole from the mould by reducing friction and extending the life of the moulds. The choice of mould treatment depends on the materials used, the specific production requirements and the desired characteristics of the...

Discover more

Discover more

The production of shoe soles involves several steps, and there are different technologies and machines used in the sole moulding process. Exemples of moulding machines Injection One of the most widespread methods to produce soles. Thermoplastic rubber, or other elastomeric materials, is melted and injected...

Discover more

Discover more

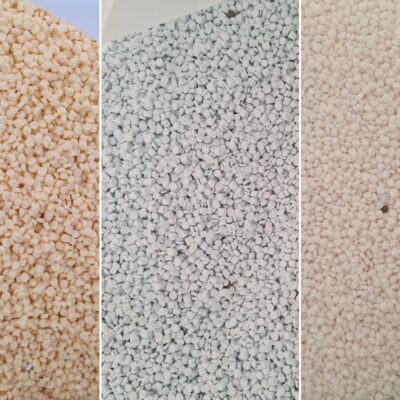

The production of moulded soles involves a variety of materials according to the requirements of comfort, strength, grip, and design. Although the first moulded soles were made of vulcanised natural rubber, today synthetic compounds are used, which can be composed of up to 15-20 different...

Discover more

Discover more

Our company with the production of automatic warehouses for sole moulds, Perseo Matrix Molds, has many customers in the field of moulded sole production. It was therefore natural for us to learn more about this reality and all its dynamics. Below you will find brief...

Discover more

Discover more