Reduce

machine times

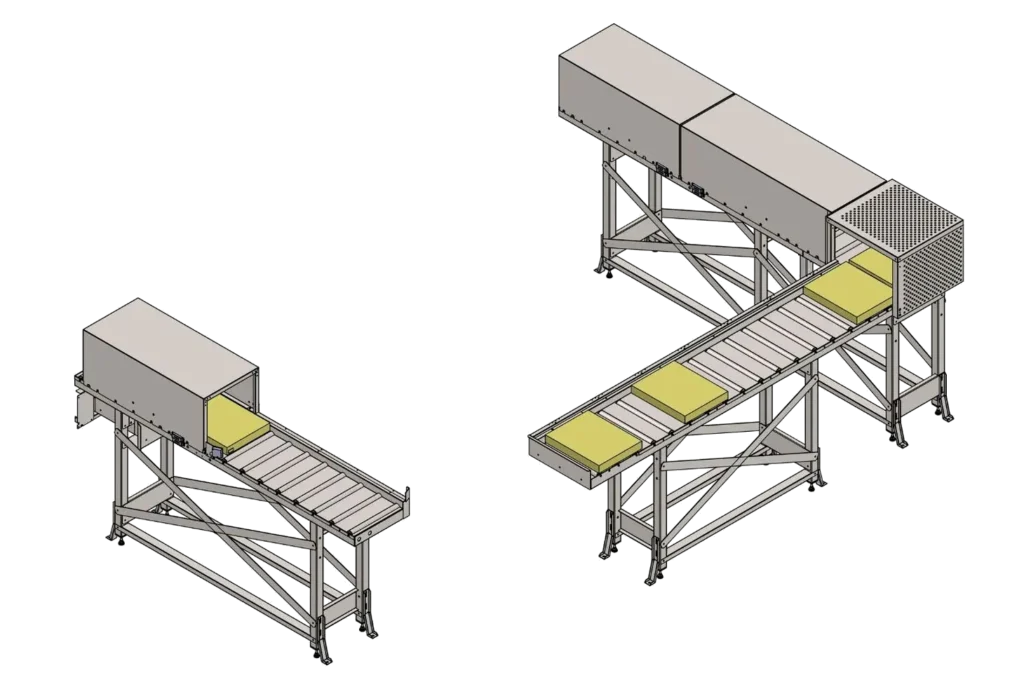

By automatically managing the picking or deposit list, the moulds will be available on the loading or unloading roller conveyor.

Reduce the operator's physical effort

The moulds are made available on the machine for the operator. He only must drag them on the trolley, not lift, and bring them to the moulding machine.

Prepare useful

moulds in advance

Thanks to the connection with the software, on the unloading roller conveyor there will be the moulds useful for production; while on the loading roller conveyor the operator will place the moulds he has already used and needs to put back.