Optimise picking times

Production times are more than reduced to zero.

Usually, the moulding machine is kept stationary waiting for the mould to come up to temperature, but with the preheating oven this is heated directly inside the automatic warehouse or on board the machine.

High-quality moulding

The oven heats the individual mould and brings it to the desired temperature, ensuring high print quality.

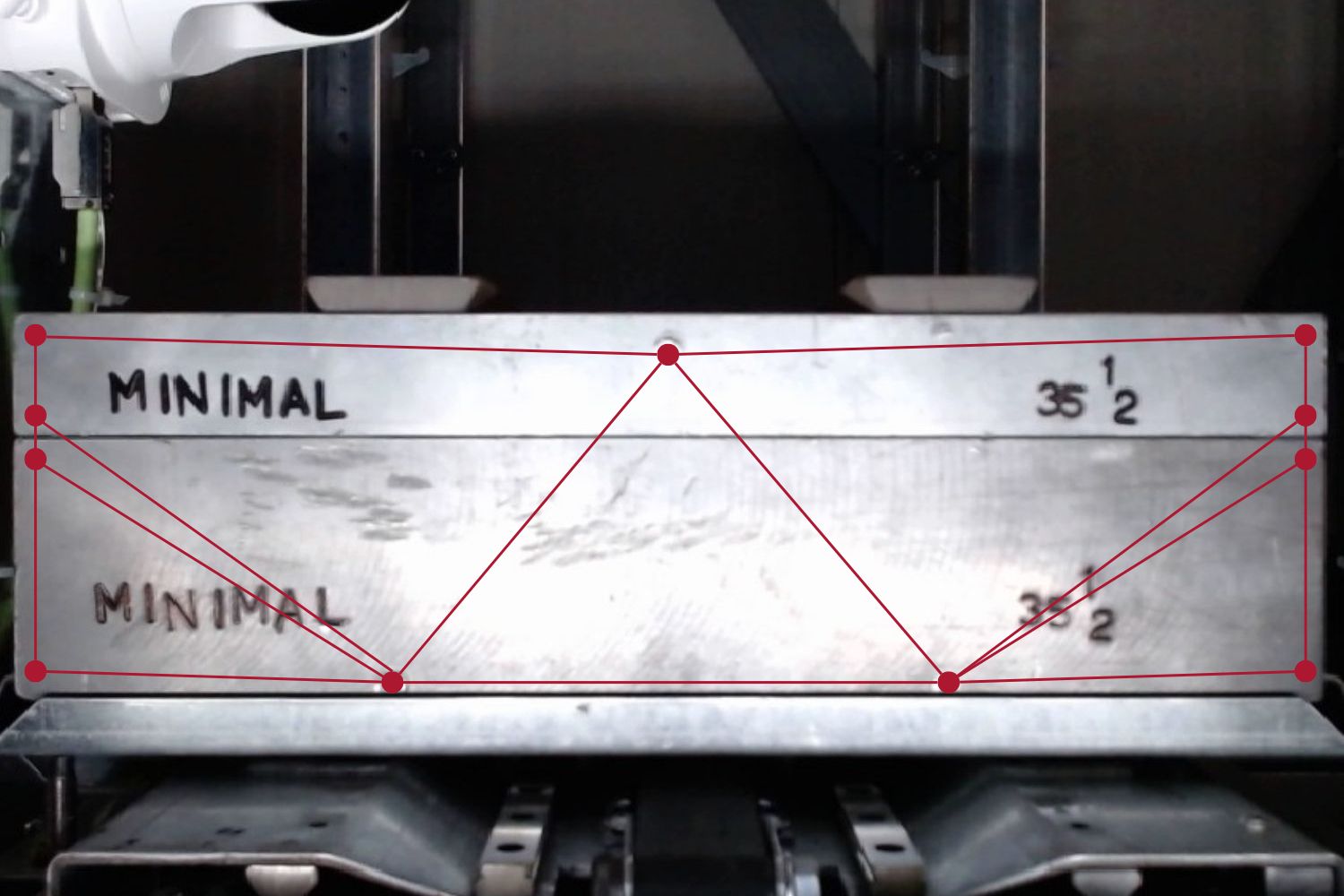

Heat the individual mould

Each oven heats one mould at a time, reducing heat loss and maintaining the desired temperature.