Perseo Matrix Moulds is the automatic warehouse specifically designed to manage sole moulds of all types and sizes.

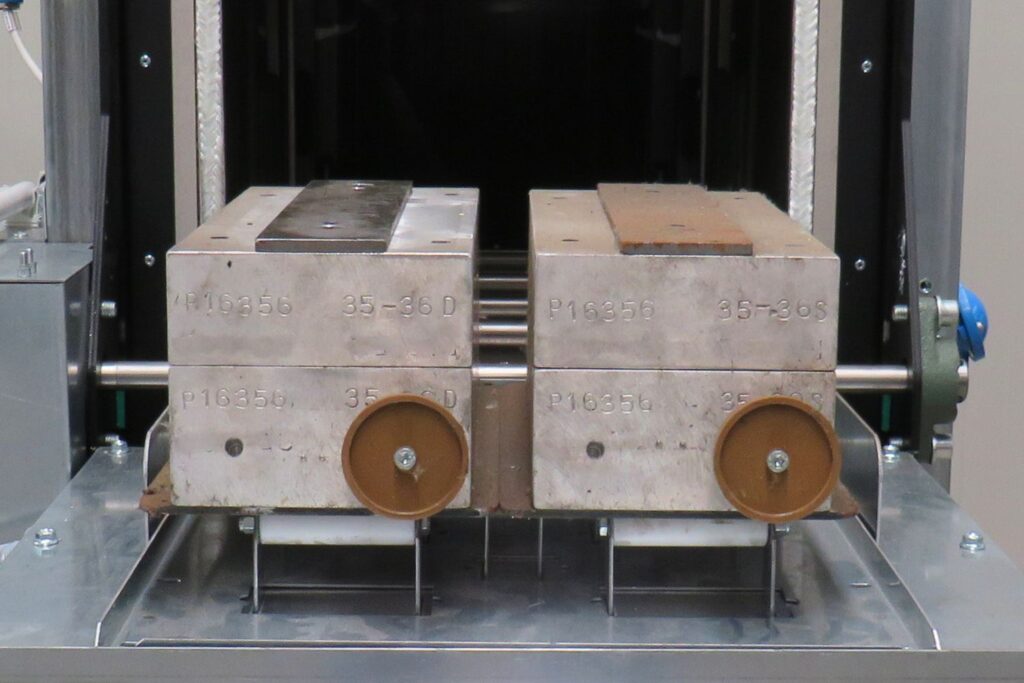

Perseo does not have a single large drawer but is equipped with small trays that allow individual mould handling. Each mould is only handled when needed and is immediately available in the bay. This eliminates operator picking errors and reduces picking times.

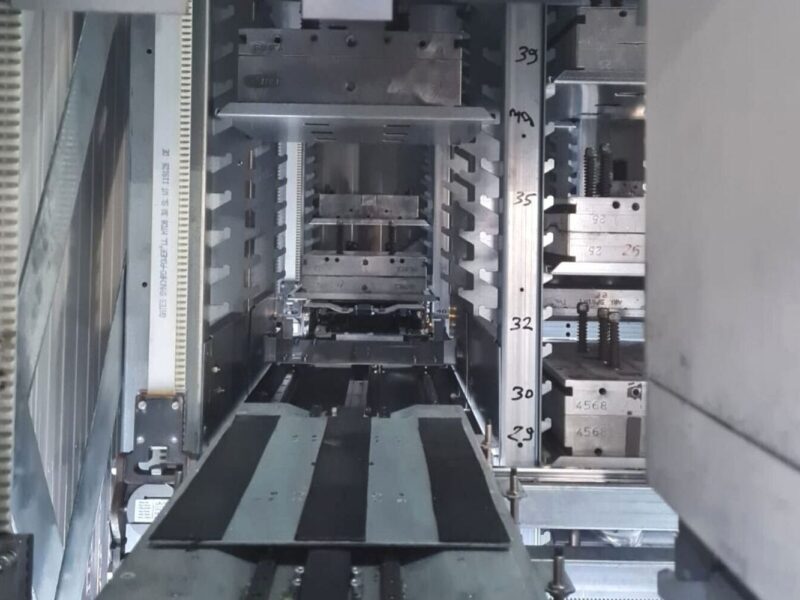

Perseo Matrix Moulds is equipped with one or more manual access bays to optimise loading and unloading times, working in masked time, and optimising item picking times. The bays are protected by double barriers, one external and one internal. Only when the inner barrier is closed will the outer barrier be opened, allowing the item contained within to be picked.

The automatic warehouse is designed for each type of mould, square, list or single, used to produce rubber, EVA or PU polyurethane soles.

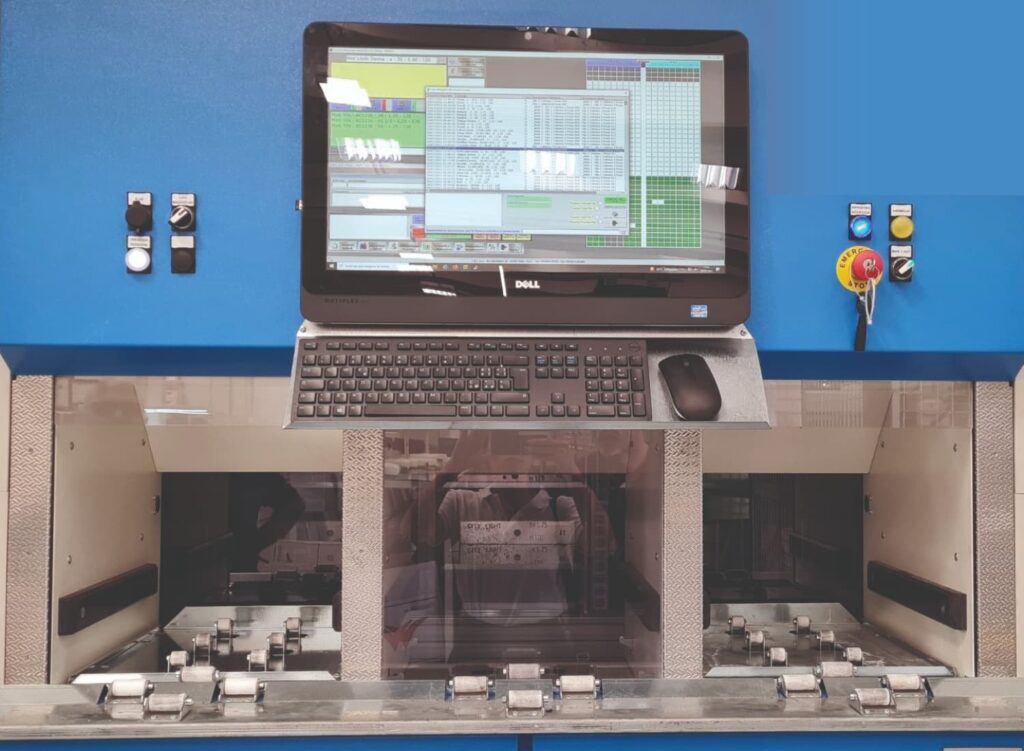

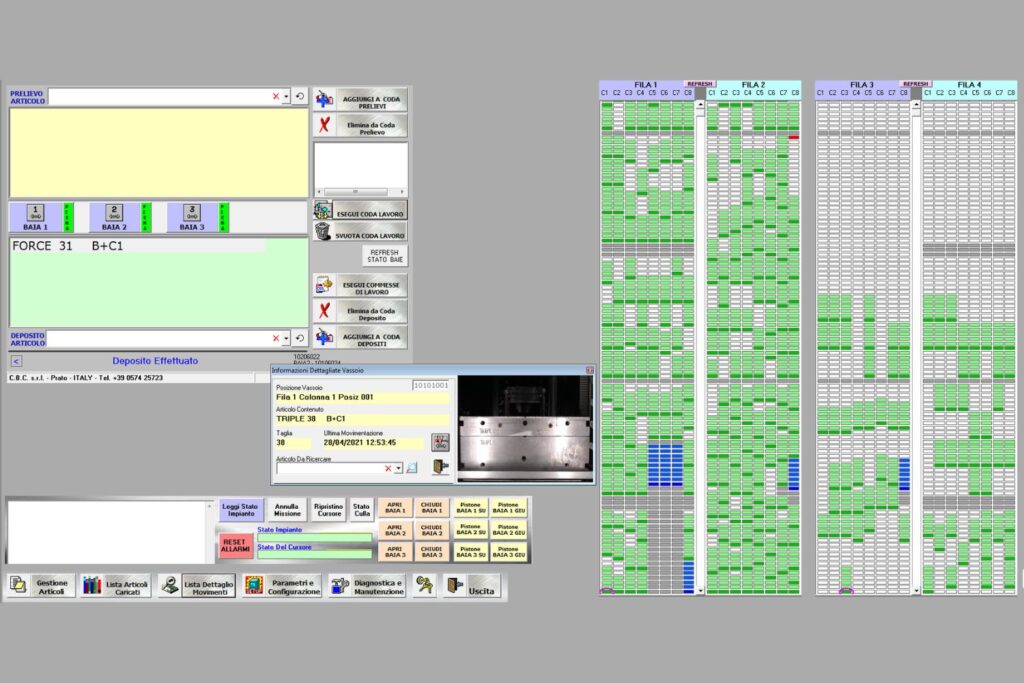

Each system is equipped with a computer, with touch screen, in which the simple and intuitive software is installed that shows the internal warehouse synoptic. In this way it is possible to see immediately the occupied and vacant position.

The warehouse software can be connected to the company management system and directly prepare the trays in the bay.

In case of emergencies or sudden jobs, the operator can pick up the items he needs by asking the automatic warehouse, in manual mode.

The Perseo Matrix automatic warehouse was created specifically for mould management, to satisfy an unfulfilled need. The objective was to store sole moulds securely within the moulding department, optimising space.

After interviewing several mould makers to understand the way they work and best meet their needs, the first prototype of the automated warehouse for mould was developed in 2013.

The advantages of the installation are considerable. If we look at a mould management with 100 mould changes per day, savings of over 4,000 hours per year are achieved.

In the case of moulds for rubber or EVA, thanks to the preheating oven the assumed benefit is 15,000 hours per year, with 100 mould changes per day.

The strength of Perseo Matrix automatic warehouse mould storage system is the Matrix System (patent-protected), which allows different mould heights to be managed, optimising storage without losing volume.

If you have moulds of different heights, the position occupied by the tray within the automatic magazine will be different depending on the type of mould deposited, ensuring high flexibility.

If, for example, you insert moulds with ejector springs, the position occupied will be greater than for classic square moulds.

The advantages of the Matrix System are:

We do not produce pre-packaged standard warehouses, but each automatic warehouse is custom-built.

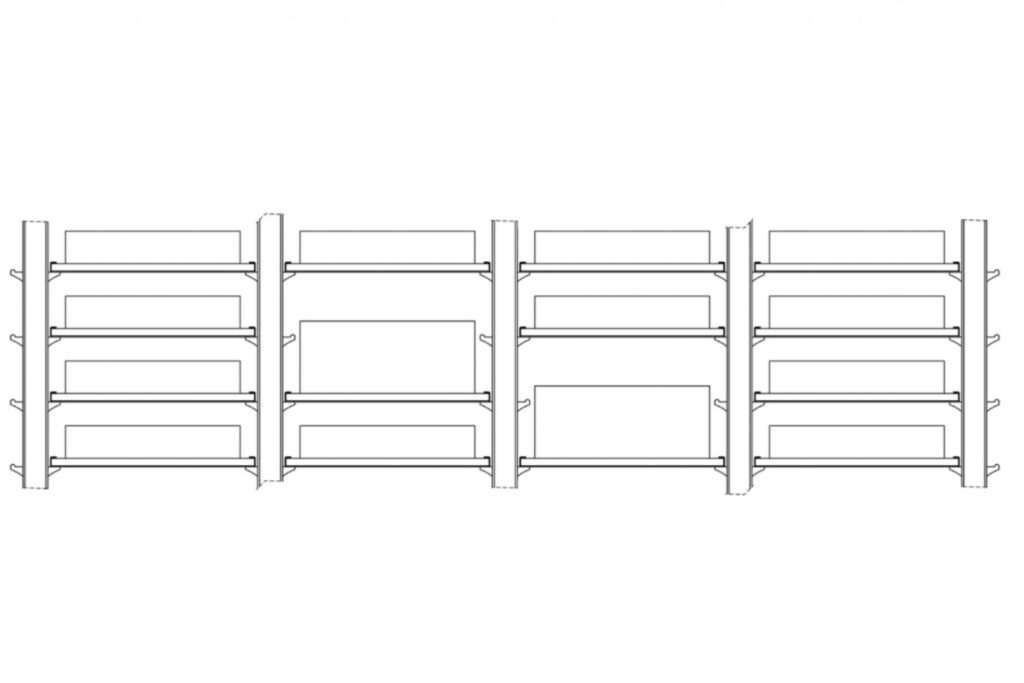

The structure of the automatic mould warehouse consists of several elements: the base body formed by one or more access bays, the computer, and the electrical cabinet. To this can be added elements in both height and width.

In this way, we build the customised warehouse, suitable for every business reality.

Wherever possible, we exploit the height inside the shed or install the warehouse outside, which will only require a small opening in the wall for the bays, greatly increasing the space in the company.

We have already realised automated warehouses up to 10 metres high and up to 16 metres wide, both indoors and outdoors.

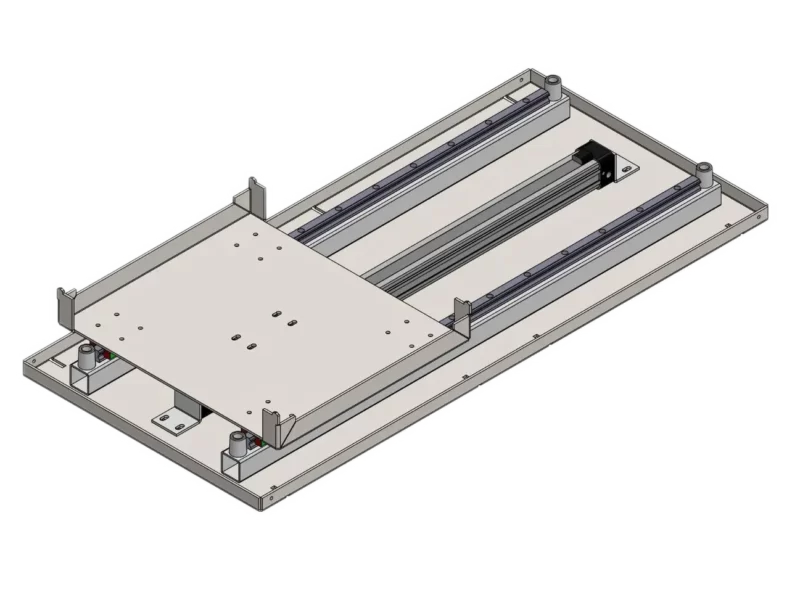

The Mould Extraction System is inserted into Perseo Matrix Moulds automatic warehouses. The system removes the effort for the operator when picking up or depositing moulds.

For pick-up, the mould will be available in the bay and thanks to the special rollers inserted under the tray, the operator simply must drag the mould, without lifting it, onto the trolley and bring it to the moulding machine.

On the other hand, for storage, the operator inserts the mould into the bay by dragging it from the trolley and it is automatically placed inside the warehouse without any effort.

The transfer system is inserted in double magazines, installed in tandem. Its function is to move moulds from one machine to another.

The Perseo automatic warehouse is flanked at the rear by another blind one, increasing depth and storage.

Inside the first warehouse there is an opening communicating with the rear warehouse in which the transfer system is inserted.

The mould is sent by the software to the transfer system and moved to the other warehouse and the cursor will place it in the position designated by the software.

The mould then, once inserted in the bay, can be placed in either the first or second machine.

The positioning of the moulds is done automatically by the software, which works in masked time and brings those useful for production closer together according to the work queue, greatly reducing picking times.

It is possible to introduce certain automations into Perseo Matrix Moulds such as:

Mould preheating oven

Automatic recognition

Loading or unloading roller conveyor

On request, the Perseo Matrix Moulds automatic warehouse can be equipped with the preheating oven for mould. The oven is used for materials that need to be heated such as rubber, EVA or PU.

The oven, installed inside the automatic warehouse, heats one mould at a time, optimising heating time and energy consumption. The moulds used for production are heated before being taken away by the operator. In this way the mould no longer needs to be heated on the moulding press machine but arrives already warm and ready for use, increasing production times.

Advantages:

Another automation that can be installed in the Perseo Matrix Moulds automatic warehouse is automatic recognition. With this system, each mould placed in the warehouse is recognised, coded and registered.

In this way it is possible to track all the moulds handled and to know their position within the automatic warehouse.

Advantages:

Perseo Matrix Moulds can be completed with loading or unloading roller conveyors, which are ideal for automating the entire picking and deposit process.

The loading roller conveyor allows the operator to leave articles directly on it and they will then be automatically loaded into the automatic warehouse. While the unloading roller conveyor provides all the moulds useful for production, contained in the bill of materials (B.O.M.), speeding up picking by the operator.

Advantages:

The single-tray Matrix range warehouse handles each item in masked time, increasing the speed of execution and reducing picking times. Each mould is quickly brought into the bay without effort.

Each machine is equipped with a customised human-machine interface, tailored to the customer's needs. It allows the operator to interact with the warehouse in a simple and intuitive way.

All Perseo warehouses are earthquake-proof and comply with work safety ruler. The structure is independent and separate from the warehouse whether it is installed indoors or outdoors.

Perseo can be connected directly to the company's management program (ERP), automating work according to the bill of material. It represents an advantage for Industry 4.0 incentives.

Optimise space within the department by utilising horizontal and vertical space. Improve space in the automatic warehouse with the Matrix System that adapts to different types of moulds.

In the Perseo automatic warehouse, all picking, and storage operations are performed with a minimum power consumption of less than 1.5 kWh. Can be connected to a 380 V socket.

VAT IT02377230970 | Cap.Soc. € 35.000 i.v. – REA PO 529606 – Pec: cbcsrlprato@pec.it | Privacy Policy | Cookie Policy