With our brand Perseo we design and manufacture custom-made logistic solutions such as tailor-made vertical automatic warehouses and automated logistics systems ideal for companies working in the sole, textile, leather, footwear and manufacturing sectors.

Our solutions optimise space and production times for the company, improving operational efficiency and guaranteeing a precise and traceable management of materials.

Each structure is developed according to the customer’s specific needs: we analyse daily and seasonal workflows, propose personalized technical solutions and follow each phase of the installation, from design to the final test.

Perseo Matrix vertical automatic warehouse is the ideal solution for optimising spaces in the department, improving production times and reducing physical effort.

Thanks to its upwards extension, the warehouse can multiply spaces in the department. The structure is earthquake-proof and can be installed either inside or outside of the production plant.

Perseo Matrix is equipped with a single tray that handles one or a few items at a time, in case of external installation it just requires a small opening in the wall.

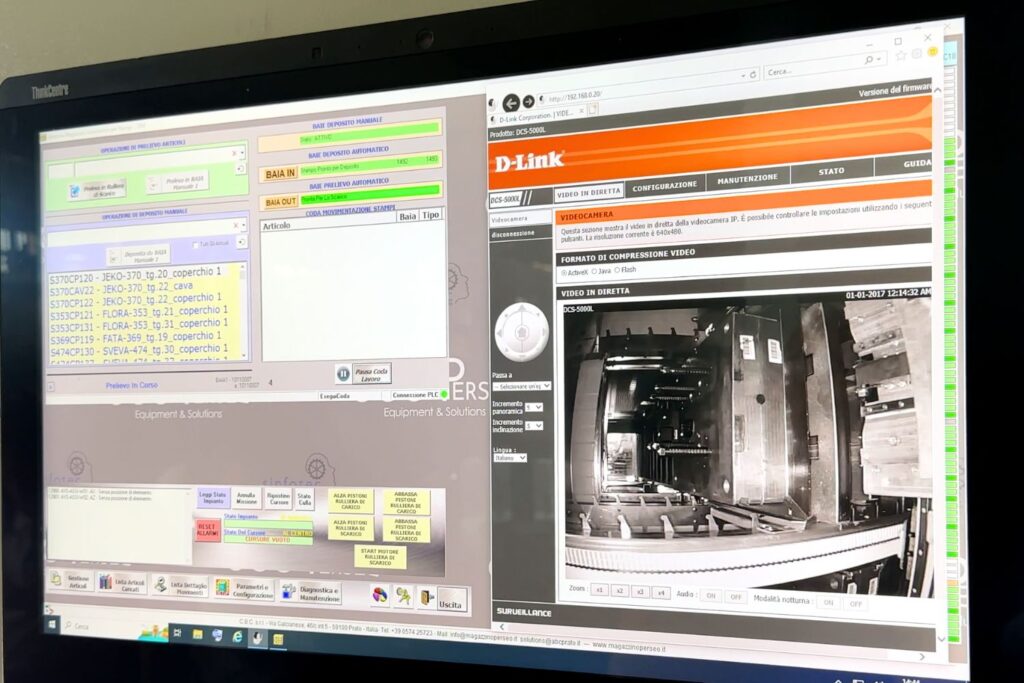

Movement of items is completely automatic: the operator requests the materials through an intuitive interface and receives the article at an ergonomic height, without the need to search for the items on the shelves and pick them up from uncomfortable positions.

It can be connected to the enterprise resource planning system (ERP) following a 4.0 or 5.0 Industry perspective. Automatically prepare items listed in the bill of materials (B.O.M.).

This way Perseo Matrix can eliminate human error, improve work safety and increase enterprise productivity.

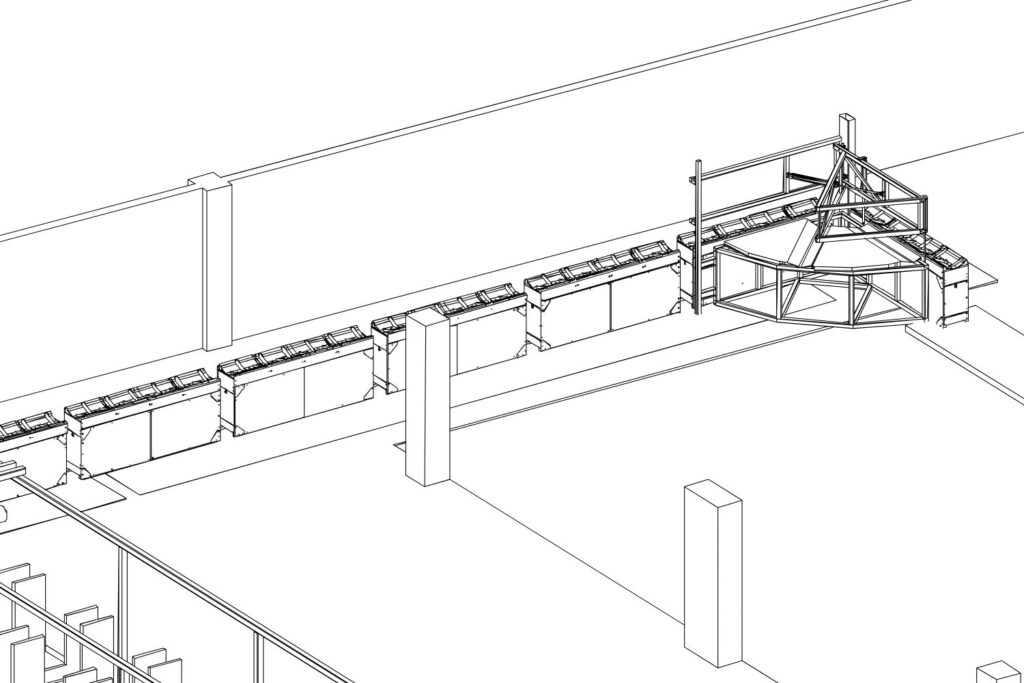

Perseo Handling automatic logistics system is designed to automatically handle materials.

Each system is custom-made according to the needs of every customer. In Perseo Handling Fabrics for example, every operation it performs is precise, quick and fully combined with the rest: from sorting through cut rolls, up to the automatic preparation of boxes ready to be shipped.

This solution automatizes internal logistics, reducing the operator’s physical effort and speeding up preparation times.

Thanks to automation, all the material it handles is traceable, avoiding the risk that items might mistakenly be sent to the wrong boxes. It is also possible to keep track of the presence of each single article.

Every structure can be inserted in a 4.0 or 5.0 Industry perspective, and it can be connected to the enterprise resource planning (ERP). All to improve productivity, efficiency and management.

Each Perseo installation, whether automatic warehouse or logistics system, is custom designed to perfectly fit into the customer’s production context.

We do not offer standardised solutions: we develop every single project in direct collaboration with the company, to answer in detail to its requirements for space and productivity.

Our technical team provides the installation of the plant, with dedicated training and continuous support both in presence and remotely.

Perseo installations can be easily linked to the enterprise resource planning (ERP), providing a complete real-time visual of the warehouse, automatically preparing the items listed in the bill of materials (B.O.M.).

The system can be part of the 4.0 or 5.0 Industry perspective, guaranteeing more production efficiency and flexibility in day-to-day operations, reducing downtime for the operators.

Our aim is to transform warehouse management into a fast, automatic and safe process, in a way that is intuitive and simple and that will improve work conditions for the operator.

VAT IT02377230970 | Cap.Soc. € 35.000 i.v. – REA PO 529606 – Pec: cbcsrlprato@pec.it | Privacy Policy | Cookie Policy