The installation of the automatic warehouse represents a strategic turning point for any company that wants to optimize space and material management, improve productivity and reduce the physical efforts of operators.

The Perseo Matrix warehouse offers an advanced solution for the organization and management of materials, ensuring greater efficiency and safety in the company thanks also to the small single tray that handles one or a few items at a time.

Automations can also be installed in the Perseo Matrix automatic warehouse, depending on the specific needs of each customer and the objects to be handled. Automations speed up the production process even more, working 7 days a week, 24 hours a day.

But what are the advantages of installing an automatic warehouse in the company?

1. Space optimization

One of the main benefits of an automated warehouse is the optimization of the space available in the department. The vertical management of materials makes it possible to reduce the area occupied, allowing surfaces to be allocated to further production activities or the introduction of new machinery.

The dimensions of the Perseo automatic warehouse are not fixed, but are customized according to the available space.

The installation of the warehouse can take place both inside the shed and outside, multiplying the available space.

2. Improvement of time and methods

With the inclusion of the automatic warehouse, there are advantages in both loading and unloading operations.

In picking operations, the operator will no longer have to search for items on the shelves, pick them from awkward positions, but they will already be ready in the bay. While in deposit operations, the operator will place the items directly in the bay and then the warehouse will place them inside where the software deems it most appropriate.

3. Increasing productivity

The automated warehouse reduces material handling time, avoiding wasted time and increasing operational efficiency. A system like Perseo Matrix ensures that materials are picked and delivered quickly and accurately, improving workflow continuity.

With the installation of automations within the warehouse, order preparation times are even faster as they operate 24 hours a day and work according to the bill of materials (B.O.M.).

4. Interconnection and Control of Enterprise Resource Planning

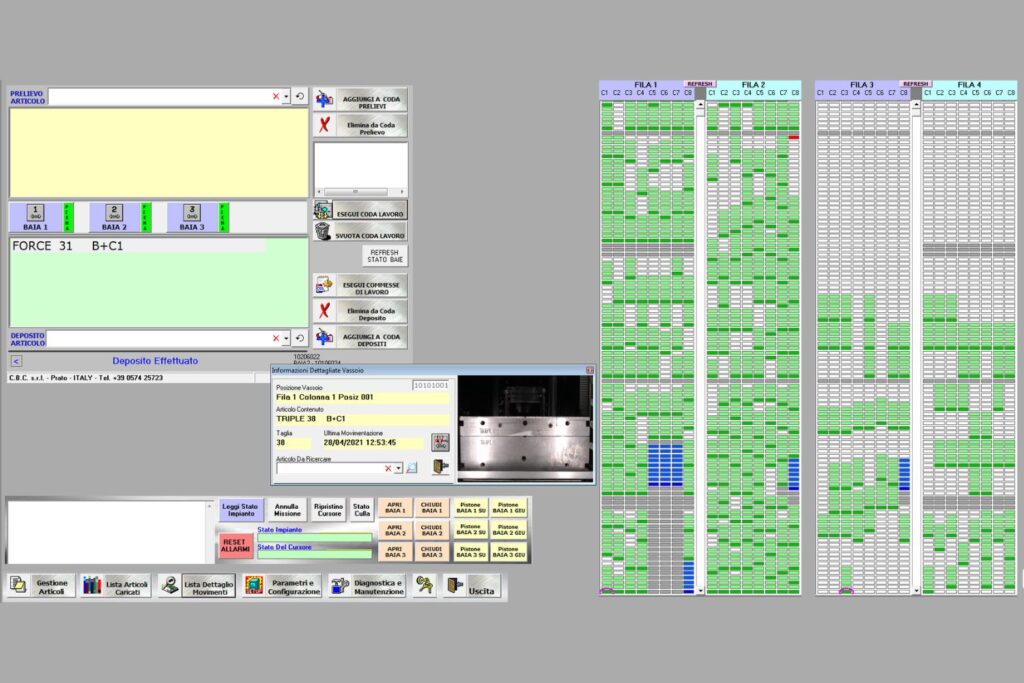

Interconnection is possible thanks to the practical and intuitive software installed in each system and customized according to the needs of each customer.

The warehouse is connected to the enterprise resource planning (ERP) by preparing customer orders as per the bill of materials or work note.

In this way, existences are monitored in real time. The warehouse records the history of all picking or deposit movements carried out, immediately calculating the actual availability in the warehouse. This is crucial for companies that work with expensive or delicate materials, such as in the textile industry.

5. Safety for operators

The use of the automatic warehouse limits the efforts of the operators, reducing musculoskeletal disorders due to the manual handling of loads. The items will no longer have to be searched for and taken from the shelves, but will be located directly in the bay at the height of the basin, convenient to pick up.

Some automations, such as automatic loading or unloading roller conveyor or rolling and cutting machine, further improve the safety and ergonomics of picking operations.

6. Long-term cost savings

While the initial investment in an automated warehouse may seem significant, the savings generated by increasing productivity, improving staff conditions and reducing the time it takes to search for items on the shelves allow you to recover expenses in a short time.

The installation of an automatic warehouse such as Perseo Matrix is a strategic choice for companies that want to improve material management, increase safety for the operators and real-time monitoring of inventories.

Thanks to the innovation and automations available, the future of industrial logistics is already a reality.